How to reduce shrinkage: Pro Tips for Smarter Inventory

- Marketing Team

- 13 hours ago

- 17 min read

If you want to get a real handle on shrinkage, you first need to know exactly where the bleeding is coming from. The truth is, most leaders over-focus on shoplifting while ignoring the far more complex—and often more damaging—internal threats that quietly eat away at profits day after day.

A real strategy has to tackle all four primary sources of loss: external theft, internal theft, administrative errors, and vendor fraud. Anything less is just plugging one hole while three others are still leaking.

Understanding the Real Sources of Retail Shrinkage

Before you throw money at new tech or roll out another policy, you have to diagnose where your losses are actually happening. Shrinkage is just a symptom of deeper operational problems, and a one-size-fits-all approach is doomed from the start.

Each category of loss is distinct, and each requires its own unique set of solutions. Let's break them down.

Here’s a quick overview of the four main culprits behind inventory shrinkage and how much they typically contribute to the problem.

The Four Main Types of Retail Shrinkage

Shrinkage Type | Description & Examples | Typical % of Total Shrinkage |

|---|---|---|

External Theft | Loss from non-employees. Includes casual shoplifting and organized retail crime (ORC) rings stealing high-value goods for resale. | 35-40% |

Internal Theft | Loss caused by employees. Examples include processing fake returns, stealing merchandise from the stockroom, or "sweethearting" at the register. | 30-35% |

Administrative Errors | "Paper shrink" caused by process failures. Includes receiving errors, incorrect pricing, misplaced inventory, and improper markdown processing. | 20-25% |

Vendor Fraud/Errors | Loss from suppliers. This can be intentional short-shipping or simple fulfillment mistakes where you pay for more than you receive. | 5-10% |

As you can see, focusing only on the most obvious threat—shoplifting—leaves more than half of the problem completely unaddressed. A truly effective strategy has to look inward.

External Theft: The Obvious Culprit

When most people hear "shrinkage," their mind jumps straight to shoplifting. And for good reason. This kind of external theft is a huge issue, covering everything from a teenager grabbing a candy bar to organized retail crime (ORC) rings hitting stores for thousands of dollars in high-value goods.

Just think about an electronics store. Small, expensive items like premium headphones or high-capacity memory cards are prime targets because they're easy to hide and have a great resale value. Without controls like locked displays or Electronic Article Surveillance (EAS) tags, the losses from this one category can quickly get out of hand.

Internal Theft: The Hidden Threat

While shoplifting gets all the headlines, internal theft by employees is often a bigger, more persistent problem. It’s also harder to stomach because it’s a violation of trust.

This isn't just about a cashier pocketing a $20 bill. It’s far more insidious. It could be a stockroom employee systematically walking out with merchandise over months or a manager processing fraudulent returns for cash. They know your systems, they know your camera blind spots, and they know how to cover their tracks.

For instance, an employee might intentionally "damage" a perfectly good item, process it as a write-off, and then simply take it home. Because they understand the inventory system, the paper trail looks clean. Fighting this requires more than cameras; it demands strong internal controls and a culture where integrity is non-negotiable.

For more specific tactics, you should check out our in-depth guide on preventing employee theft.

Administrative and Paperwork Errors

This is the silent killer of profit margins. Administrative errors, or "paper shrink," are often the most underestimated source of loss, but they can be just as damaging as outright theft. These are the thousands of small mistakes that add up to big numbers through broken daily processes.

Just think about these all-too-common scenarios:

Receiving Errors: A shipment of 100 units comes in, but the receiving clerk miscounts and enters 110 into the system. Just like that, your inventory now shows 10 units that never existed, creating an instant variance.

Pricing Mistakes: An item is priced incorrectly in the point-of-sale system, causing it to be sold for far less than its actual value. Every sale becomes a direct hit to your margin.

Incorrect Markdowns: An employee improperly processes a damaged goods claim, writing off inventory that was actually sellable or could have been returned for credit.

These aren't malicious acts, but their financial impact is just as real. The only way to stop this kind of bleeding is by tightening up your operational procedures and training.

Vendor Fraud and Supplier Errors

Finally, your shrinkage problem might be starting before products even make it onto your sales floor. Vendor fraud happens when you don’t actually get what you paid for.

Sometimes it's deliberate, like a dishonest supplier who consistently short-ships an order. More often, it's just a simple mistake in their fulfillment process. Either way, if your receiving team isn't meticulously checking every single delivery against the purchase order, you could be losing money right at the loading dock without ever knowing it.

Building a Culture of Prevention Through People and Policy

Technology and cameras are crucial, but let's be honest: your first and best line of defense against shrinkage is always your team. A disengaged employee sees loss prevention as someone else's problem. An empowered one sees it as their own responsibility to protect the business.

Building this culture of prevention isn't about creating a police state. It’s about setting crystal-clear expectations with smart policies and continuous training. The goal is to transform every team member from a passive observer into an active partner in your store's security. That shift is the key to stopping loss before it ever happens.

Crafting Policies That Actually Work

Generic, boilerplate policies are easily ignored. Effective loss prevention policies need to be specific, actionable, and tied directly to the daily grind of your staff. They remove the guesswork and give your team a clear playbook for high-risk situations.

A vague rule like "handle cash carefully" is useless. What you need is a rigid protocol. This approach drives consistency and makes it much harder for mistakes—or intentional fraud—to slip through.

For instance, a rock-solid cash handling policy should include:

Mandatory manager verification for all voids and no-sale transactions.

Dual-employee verification during end-of-day cash counts to build in accountability.

Strict limits on the amount of cash in any register, with clear procedures for moving excess to a drop safe.

Clear protocols for accepting large bills, including the mandatory use of counterfeit detection pens.

Your return policy needs to be a fortress against fraud, but without creating a miserable experience for legitimate customers. This means defining non-negotiable rules, like always requiring an original receipt for cash refunds or issuing store credit for non-receipted returns after verifying a customer's ID.

A well-defined policy is a tool for empowerment. It gives your employees the confidence to enforce rules consistently and the framework to make the right decision under pressure, which is fundamental to any strategy for how to reduce shrinkage.

Moving Beyond Onboarding Training

Loss prevention training cannot be a one-and-done event during orientation week. If you want to create a lasting culture of security, it has to be an ongoing conversation that keeps awareness high and skills sharp.

Regular, bite-sized training sessions are far more effective than an annual seminar nobody pays attention to.

Think about running short, focused huddles before shifts to discuss recent trends or potential threats. These quick check-ins reinforce the importance of vigilance and make loss prevention a daily topic—not a forgotten rule buried in a handbook.

This is where you can see a dramatic impact. U.S. retailers faced a staggering $45 billion loss from shoplifting alone, part of a global retail shrink crisis that hit $112.1 billion. Yet, retailers who rolled out comprehensive frontline staff training saw shrinkage rates drop by up to 30%. Why? Because empowered employees are quicker to spot suspicious behavior and intervene safely. You can dig into more insights on the impact of training on retail shrinkage rates on netsuite.com.

Empowering Employees to Spot Red Flags

Your training has to give employees practical skills to identify and respond to suspicious behavior. This isn't about turning cashiers into security guards; it’s about sharpening their observational skills and giving them a clear, safe protocol to follow.

Focus on teaching recognizable, non-confrontational customer service techniques that naturally deter theft. Simply instructing your team to offer friendly, prompt assistance to every single person who walks in is one of the most powerful deterrents there is.

Train your team to notice specific behaviors, such as:

Individuals who avoid eye contact and seem more interested in camera locations than the actual merchandise.

Shoppers carrying bulky, empty bags or wearing heavy coats in the middle of summer.

Groups that enter at once to create a deliberate distraction in one area while another person pockets items somewhere else.

When an employee spots these red flags, they need a clear, risk-free action plan. That plan should almost always be to alert a manager or a designated loss prevention team member—never direct confrontation. The goal is to observe and report. This approach ensures employee safety while enabling effective incident management, turning every person on your sales floor into a valuable sensor.

Tightening Your Operational and Inventory Controls

While theft always seems to grab the headlines, the silent drain from administrative errors and broken internal processes can be just as devastating. These are the unforced errors—miscounts, receiving mistakes, and pricing slip-ups—that quietly eat away at your margins day after day.

Reinforcing your operational and inventory controls is all about instilling precision and consistency into every single step of your workflow, from the moment a truck hits the loading dock to the final scan at the checkout counter. This isn't just about catching mistakes after they happen; it's about building a system so robust that those mistakes rarely happen in the first place.

The Power of Precision at Receiving

Your loading dock is the first and most critical checkpoint for inventory accuracy. A single mistake here creates phantom inventory that will cascade through your entire system, leading to stockouts, bad counts, and, ultimately, shrinkage. A bulletproof receiving process is completely non-negotiable.

This means moving way beyond a quick visual check. Your team has to meticulously verify every delivery against its purchase order and ASN (Advance Shipping Notice). Every single carton, every single unit.

For instance, a classic blunder is receiving a case of 24 units but logging it as a single item. That one keystroke creates an immediate variance of 23 items that won't get resolved until a physical count reveals the discrepancy months down the road.

To shut this down, enforce a strict "no scan, no move" policy. Every item or case must be scanned into your system upon arrival. You should also consider adding these protocols:

Two-Person Verification: For high-value shipments, require two employees to sign off on the count before it gets entered into your inventory management system.

Quarantine Mismatches: If a delivery doesn't match the purchase order, it should never enter your general inventory. Move it to a designated quarantine area until the discrepancy is resolved with the vendor.

Cycle Counts Over Annual Inventories

The traditional wall-to-wall annual inventory is a massive, disruptive event that only gives you a single snapshot in time. A far more effective approach for managing and reducing shrinkage is implementing a consistent cycle counting program.

Cycle counting involves breaking down your inventory into small, manageable sections and counting them on a rotating, ongoing basis. This approach turns inventory management from a once-a-year headache into a continuous, proactive process.

By counting your highest-value "A" items weekly and your slower-moving "C" items quarterly, you can identify and correct discrepancies in near real-time, long before they become significant financial losses.

This constant verification not only dials in your accuracy but also helps you pinpoint the root causes of errors. If you consistently find variances in the same department or with the same product type, you know exactly where to focus your process improvement efforts. Implementing robust Top Retail Inventory Management Best Practices is the only way to get this under control.

Inventory control is a game of inches, and different techniques work better for different types of retail environments. Here’s a quick breakdown of some of the most effective methods.

High-Impact Inventory Control Techniques

Technique | Primary Benefit | Best For |

|---|---|---|

ABC Analysis | Prioritizes counting efforts on high-value "A" items. | Retailers with diverse product values (e.g., electronics, jewelry). |

Just-In-Time (JIT) | Minimizes on-hand inventory, reducing holding costs and theft opportunities. | High-turnover environments like fast fashion or grocery. |

First-In, First-Out (FIFO) | Ensures older stock is sold first, preventing spoilage and obsolescence. | Businesses with perishable goods (e.g., food, cosmetics). |

Perpetual Inventory | Provides a real-time view of stock levels through continuous updates. | High-volume retailers needing constant accuracy (e.g., big-box stores). |

Choosing the right mix of these techniques can dramatically improve your control and cut down on preventable losses.

Managing Damaged Goods and Vendor Audits

How you handle damaged goods can be another hidden source of shrinkage. Without a clear and consistent process, items might get written off unnecessarily or disposed of improperly, leading to a total loss. A structured approach is key to recovering as much value as possible.

Create a dedicated area for damaged items and use clear disposition codes: "Return to Vendor," "Repairable," or "Write-Off." This simple step prevents sellable merchandise from being tossed out and creates an auditable trail for every item that doesn't make it to the sales floor. For a deeper look at process-driven loss prevention, explore these modern internal control best practices.

Equally important are regular vendor audits. Inefficiencies in stores, not just theft, drive massive shrinkage, with some retailers losing 5.5% of gross sales to process failures. Retailers who have implemented automated systems have seen administrative errors drop by up to 50%.

For example, after rolling out real-time inventory tracking, major chains like Target cut their out-of-stock losses by 35%—a direct result of improved operational controls. By tightening these internal processes, you can stop bleeding profit from preventable errors and build a more resilient, accurate, and profitable operation.

Using Smart Technology to Detect and Deter Loss

Manual processes and human observation just don't cut it anymore when you're up against modern retail shrinkage. If you want to gain a real advantage, you have to get out of a reactive crouch and onto the offensive. This is where smart technology becomes your most valuable player, giving you the tools to not only catch incidents but to predict and stop them before they even happen.

An integrated technology stack lets you see patterns the human eye would completely miss. It turns mountains of operational data into intelligence you can actually use. This is how you finally learn to anticipate threats instead of just cleaning up after them.

Upgrading from Surveillance to Intelligence

Let’s be honest, traditional CCTV systems that just record footage for you to review later are relics. Modern loss prevention runs on intelligent video analytics, which use AI to actively monitor feeds in real time. These aren't just cameras; they're digital lookouts trained to recognize specific behaviors and send instant alerts when a potential threat pops up.

For instance, AI-powered systems can automatically flag suspicious activities like:

Loitering: Someone hanging around a high-theft area for way too long without actually shopping.

Shelf Sweeping: The classic organized retail crime (ORC) move of clearing a shelf of high-value items in seconds.

Concealment: The tell-tale movements of someone trying to hide merchandise in a bag or under their clothes.

When an alert is triggered, your managers or security team get a notification on the spot, allowing for immediate intervention. This turns your camera network from a passive recording system into an active, intelligent partner in loss prevention.

Securing High-Value Merchandise

For your most valuable and frequently stolen products, just watching isn't enough. This is where technologies like Electronic Article Surveillance (EAS) and Radio-Frequency Identification (RFID) add a critical layer of defense, making it a whole lot harder for items to walk out the door unpaid.

EAS systems—those familiar tags that set off an alarm at the exit—are a fantastic visual deterrent. RFID takes it a step further by giving each item its own unique digital fingerprint. This not only foils theft but also delivers pinpoint inventory tracking, boosting accuracy and cutting down on the administrative errors that contribute to shrinkage.

The goal here isn't just to make theft harder; it's to create an environment where the risk of getting caught feels immediate and unavoidable. That psychological deterrent is every bit as important as the physical barrier the technology creates.

And don't forget to think beyond your four walls. Securing your entire property with robust physical barriers is just as crucial. You can find great resources on top commercial security gate solutions to help lock down your facility's perimeter.

Uncovering Fraud at the Point of Sale

The point of sale (POS) is a hotbed for shrinkage, from bogus returns to employee "sweethearting," where items are deliberately not scanned for friends and family. Advanced POS analytics systems are designed to sniff this out by integrating transaction logs with video surveillance, automatically flagging suspicious patterns that are otherwise impossible to find.

These systems can spotlight high-risk transactions for review, like an unusual number of voids, "no-sale" drawer openings, or manual discounts tied to a specific cashier. By linking these transactional red flags to the corresponding video footage, you can quickly determine if an action was an honest mistake or outright theft. Spotting these hidden vulnerabilities is a game-changer. You can get a much deeper look by reviewing specialized resources on insider threat detection tools that are built to address these internal risks.

The financial return on these tech investments can be massive. Early adopters of computer vision and analytics are already reporting 20-40% drops in theft-related shrink. A real-world standout is CVS, which piloted computer vision in 500 stores and slashed ORC losses by 45% by using predictive alerts on high-value items.

When you integrate these smart technologies, you create a powerful, multi-layered defense. Each component works in concert—AI video spots suspicious behavior, EAS/RFID tags protect specific products, and POS analytics expose internal fraud—to provide total protection for your assets and your profits. This is how you move from playing defense to offense in the ongoing fight against shrinkage.

Creating a Fair and Effective Investigation Process

When you get a red flag—a potential theft or a major policy breach—your response has to be fast, systematic, and fair. Fumbling an investigation is a surefire way to invite legal trouble, crush employee morale, and ultimately, fail to fix the root cause. A well-defined, consistent process isn't just about protecting the business; it protects the rights of everyone involved.

The goal here isn't just to catch someone in the act. It's to gather facts without bias, make a decision based on evidence, and figure out the process failures that let the incident happen in the first place. This turns the investigation from a reactive fire drill into a powerful tool for preventing the next one.

Establishing a Clear Investigation Protocol

Long before an incident blows up, you need a documented protocol that spells out every single step of an internal investigation. This isn't the time for improvisation. Consistency is your best defense, both legally and culturally.

Your management and loss prevention teams need to be trained on this exact procedure, which should clearly define:

Who has the authority to launch and lead an investigation.

The immediate first steps for preserving evidence, like saving specific video footage or isolating transaction logs.

Clear guidelines for when to pull in other departments like Human Resources or Legal.

A rock-solid chain of custody for every piece of evidence you collect.

Having this structure ensures every investigation starts on the right foot, preventing rookie mistakes that could torpedo the entire process. Without a framework, you’re just winging it, and that almost always leads to biased and inconsistent outcomes.

An investigation is a fact-finding mission, not a witch hunt. The process must be designed to uncover the truth, regardless of where it leads, while treating every individual with dignity and respect.

Conducting Structured and Compliant Interviews

The interview is easily the most sensitive—and most critical—part of any investigation. Your objective is simple: gather information, not force a confession. Using a structured, non-accusatory approach is the only way to have a productive and legally compliant conversation.

Always, and I mean always, conduct interviews with two trained investigators present. One person leads the questioning while the other takes detailed, verbatim notes. This gives you a witness and ensures your documentation is airtight. The interview itself should happen in a neutral, private space where the employee feels as comfortable and safe as possible.

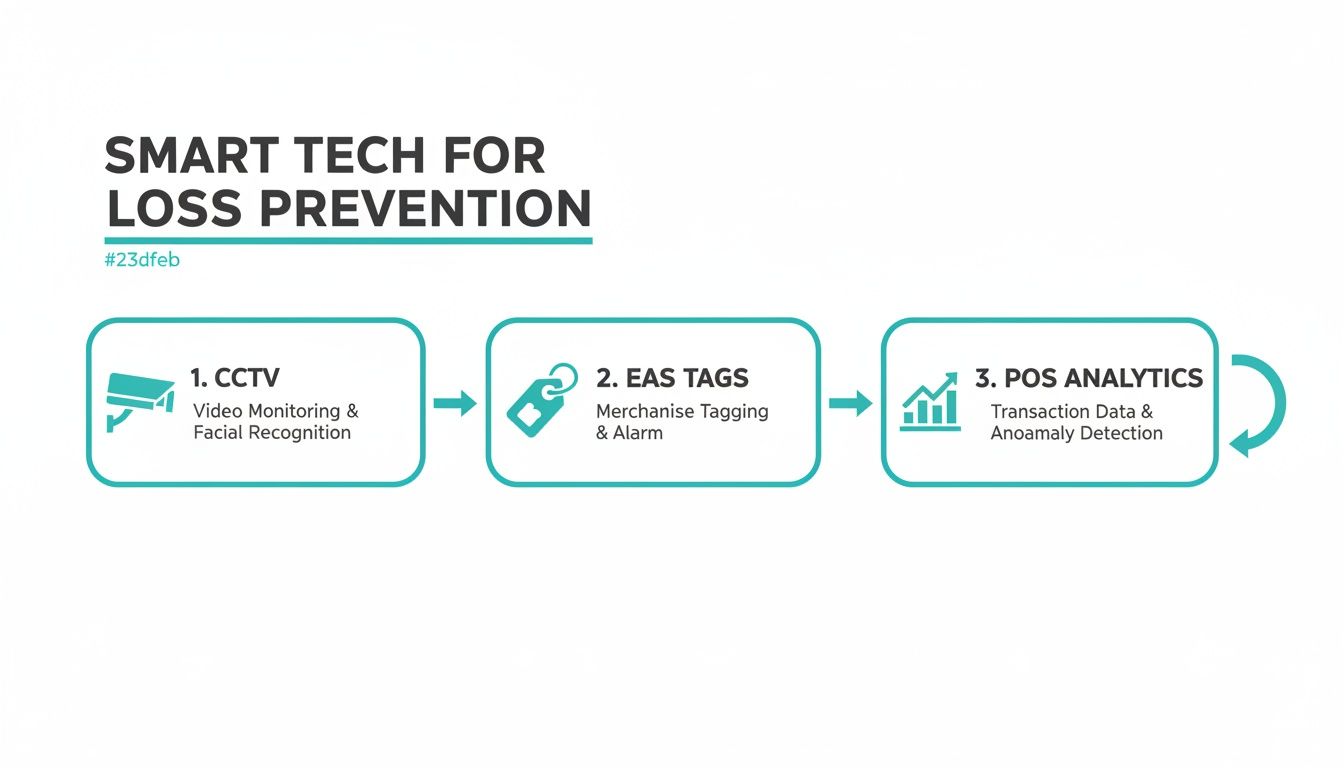

The flowchart below shows how modern technology feeds into the process, giving you the initial data that might trigger an investigation in the first place.

As you can see, data from CCTV, EAS tags, and POS analytics can be woven together to create a clear chain of evidence for a systematic review.

From Disciplinary Action to Process Improvement

Once all the facts are on the table, the investigation team—along with HR and legal counsel—needs to review the findings and decide what's next. This decision has to be based only on the evidence and applied consistently according to your company’s disciplinary policies.

The outcome can vary quite a bit:

Exoneration: If the evidence doesn't back up the initial concern, the employee is cleared, and the case is closed. Simple as that.

Coaching or Retraining: For honest mistakes or minor policy slip-ups, more training is often the most constructive path forward.

Formal Disciplinary Action: This could mean anything from a formal warning to suspension or termination, depending on how serious the offense is and the employee’s history.

Reporting to Law Enforcement: For clear-cut cases of criminal theft, getting the police involved may be necessary to pursue prosecution and restitution.

No matter the outcome, the final step is to dig into the root cause. Was it a loophole in your return policy? A blind spot in your camera coverage? A gap in your training program? Use what you learned to tighten your controls and stop the same thing from happening again. This closes the loop, turning a negative event into a catalyst for strengthening your entire loss prevention strategy.

Turning Shrinkage Reduction into an Ongoing Practice

Getting a handle on shrinkage isn't a project with a finish line. It’s a fundamental shift in how your business operates day-to-day. You’ve built the policies, tightened the controls, and rolled out the tech—now, the real work begins. This is about weaving accountability and measurement so deep into your company's rhythm that it becomes second nature.

This final stage moves you from reactive fire-fighting to proactive performance management. It’s where you measure the real-world impact of your strategies and, most importantly, create a culture where every single team member feels ownership over the results.

Identifying the Right KPIs to Track

You can't manage what you don't measure. If you want to know if all this effort is actually working, you need to track a handful of key performance indicators (KPIs) that give you a clear, objective view of your progress. These metrics are the heartbeat of your entire loss prevention program.

Forget about just looking at one big, company-wide shrink number. You have to get granular. The most effective KPIs give you actionable insights that tell you not just what happened, but where and why.

Here are the core metrics you should be watching:

Shrinkage as a Percentage of Sales: This is the classic metric, calculated as (Total Shrink Value / Total Sales) x 100. It ties your losses directly to revenue, giving everyone a clear financial context for the problem.

Inventory Accuracy Rate: Calculated as (1 - (Absolute Variance Value / Total Inventory Value)) x 100, this KPI is a direct measure of how precise your stock records are. An accuracy rate north of 98% is a strong sign of tight operational control.

Cycle Count Variance: Don't just look at the final number. Track the value and frequency of discrepancies you find during regular cycle counts. This gives you a near real-time pulse on your inventory's health.

Creating Dashboards for Transparency

Data that’s locked away in a spreadsheet might as well not exist. To drive real change, your KPIs have to be visible, accessible, and dead simple to understand for everyone from the stockroom team to the C-suite. Simple, visual dashboards are the best way to make that happen.

Build a weekly or monthly dashboard that puts your core loss prevention metrics front and center. Use clear charts and color-coding—green for on-target, yellow for caution, and red for immediate attention—to make the information instantly digestible.

A transparent dashboard isn't just a reporting tool; it's a conversation starter. When everyone can see the numbers, it creates a shared sense of purpose and encourages proactive problem-solving across all departments.

Share these dashboards everywhere. Post them in break rooms, review them in daily huddles, and make them a standard agenda item in your management meetings. This constant visibility reinforces the message that cutting shrinkage is a collective responsibility, not just a job for the LP team.

Fostering a Lasting Culture of Accountability

Policies and metrics give you the framework, but a lasting culture of accountability is what truly sustains a loss prevention program over the long haul. This kind of culture is built on continuous engagement, genuine recognition, and wide-open communication.

Think about how you can keep your team actively involved. This isn't about fostering an environment of suspicion; it’s about celebrating wins and reinforcing the right behaviors.

Launch a Recognition Program: Publicly acknowledge individuals or teams who spot a process gap, report a potential issue, or consistently crush their inventory accuracy goals. A simple "Shrink Buster of the Month" award can go a surprisingly long way.

Maintain Open Communication Channels: Create a safe, anonymous way for employees to report concerns or suggestions without any fear of reprisal. This not only helps you uncover hidden issues but also shows your team that you genuinely value their eyes and ears on the floor.

Connect Their Work to the Bottom Line: Regularly explain how reducing shrinkage protects profits, which in turn secures jobs and allows for investments back into the business and its people. When your team truly understands the "why," their commitment deepens.

By making shrinkage reduction a visible, measured, and celebrated part of your company culture, you transform it from a temporary initiative into a permanent operational discipline. This is how you protect your assets for the long haul.

At Logical Commander Software Ltd., we believe in proactive prevention over reactive cleanup. Our E-Commander platform is designed to identify early signals of internal risk and misconduct, enabling you to act fast while preserving employee dignity and ensuring full compliance. Instead of waiting for shrinkage to hit your bottom line, our AI-driven system helps you build a culture of integrity from the ground up, turning risk into actionable, ethical intelligence. Discover how our unified operational platform can strengthen your governance and protect your organization at https://www.logicalcommander.com.

%20(2)_edited.png)